What Are Reo Bars and Why Are They Important in Construction?

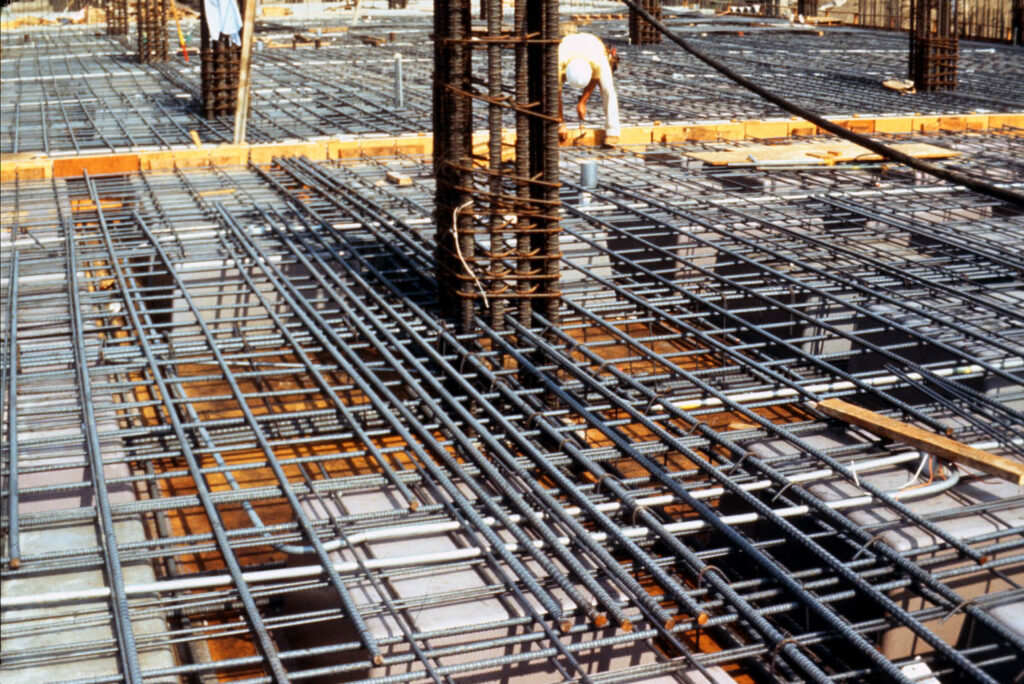

Reo bars, also known as reinforcement bars or rebars, are essential components in modern construction projects. These steel bars provide a strong internal support system within concrete structures, turning regular concrete into reinforced concrete with impressive strength capabilities.

The Role of Reo Bars in Construction

Reo bars play a crucial role in construction by:

- Enhancing tensile strength: While concrete is strong under compression, it requires reinforcement to withstand tension forces.

- Preventing cracking: By strategically placing reo bars, we can control the shrinkage and thermal movement of concrete, minimising the risk of cracks.

- Distributing loads: Reo bars effectively transfer structural loads throughout the building, ensuring even distribution of weight.

- Increasing durability: Properly reinforced concrete structures have a longer lifespan and can withstand various environmental conditions.

Buy reo bars requires careful consideration of supplier credibility and reliability. Specialised construction material suppliers offer distinct advantages for both small-scale and large construction projects:

The Importance of Choosing the Right Reo Bar Specifications

The selection of appropriate reo bar specifications directly impacts the structural integrity of your project. For example, a 12mm reo bar has different load-bearing capabilities compared to a 32mm variant. Therefore, it is crucial to choose the right size based on your specific construction requirements.

Your choice of reo bar grade also affects several factors:

- Building compliance standards

- Cost-effectiveness

- Long-term structural performance

- Safety margins

Selecting the right combination of reo bars is fundamental to the success of construction projects, whether they are small residential builds or large commercial developments.

Find more on: How to Choose Between F14 Grade Plywood and F17 Grade Plywood for Formwork

How Do You Choose the Right Reo Bar Size for Your Construction Project?

Selecting the right reo bar size depends heavily on your project’s scale and specific requirements. Small-scale residential projects and large commercial developments demand different approaches to reinforcement.

Small-Scale Residential Projects

- 10mm-12mm diameter bars suit most residential foundations

- 16mm bars for load-bearing walls and columns

- Spacing typically ranges from 200mm to 250mm apart

- Light-duty mesh options available for concrete slabs

Large Commercial Developments

- 20mm-32mm diameter bars for heavy structural elements

- 25mm-40mm bars for high-rise buildings and bridges

- Tighter spacing requirements (150mm-200mm)

- Multiple layers of reinforcement common

Key Factors for Size Selection

Load-Bearing Requirements

- Dead loads (permanent structural weight)

- Live loads (occupancy, equipment, vehicles)

- Environmental factors (wind, seismic activity)

Design Specifications

- Concrete grade and strength

- Cover requirements

- Structural element dimensions

- Building code compliance

Project-Specific Considerations

- Soil conditions

- Building height and span lengths

- Construction method

- Budget constraints

The structural engineer’s calculations determine the exact reo bar specifications needed for your project. These calculations factor in safety margins and local building regulations to ensure structural integrity. You’ll need detailed construction drawings and specifications to guide your reo bar selection process. Learn more about integrity on https://med.stanford.edu/md/mdhandbook/section-2-general-standards/section-2-4-school-of-medicine-professional-principles.html

What Role Do Regional Standards Play in Reo Bar Selection?

Regional standards are important guidelines that govern the quality, specifications, and use of reinforcement bars in construction projects. In Australia and New Zealand, the AS/NZS 4671 standard sets out detailed requirements for steel reinforcing materials.

Key aspects of AS/NZS 4671 include:

- Minimum yield strength requirements

- Chemical composition specifications

- Surface geometry standards

- Bend test criteria

- Fatigue resistance parameters

The British Standard BS4449/2005 provides additional guidance, especially relevant for international projects or when using imported materials. This standard focuses on:

- Tensile strength specifications

- Elongation requirements

- Weldability criteria

- Carbon equivalent values

- Bond classification systems

These standards directly affect how you choose your materials:

- Grade Selection: Standards dictate specific strength grades (250MPa, 500MPa)

- Size Requirements: Diameter specifications for different applications

- Testing Protocols: Mandatory quality control procedures

- Documentation: Required certificates and compliance reports

The location of your project determines which standards apply. Urban developments in Sydney might need to follow additional local building codes, while rural projects in Queensland could have different requirements.

If you don’t comply with these standards, it can lead to:

- Project delays

- Failed inspections

- Structural integrity issues

- Legal complications

- Insurance claim rejections

Working with certified suppliers who understand and follow these regional standards helps ensure your construction project meets all necessary requirements. These suppliers keep their documentation up to date and can provide guidance on selecting materials that comply with the standards. Click here to find more about documentation.https://health.uconn.edu/healthcare-compliance-privacy/2022/06/27/medical-student-documentation/

Where Can You Buy Reo Bars for Your Construction Project?

Dedicated Construction Material Suppliers

- Direct access to certified reo bar products

- Technical expertise and product knowledge

- Bulk ordering capabilities

- Competitive pricing structures

- Custom cutting and bending services

Steel Merchants and Distributors

- Wide range of steel products

- Multiple warehouse locations

- Established supply chains

- Stock availability guarantees

- Delivery scheduling options

When selecting your reo bar supplier, prioritise these essential factors:

Experience and Reputation

- Years in operation

- Industry certifications

- Client testimonials

- Project portfolio

- Quality assurance processes

Product Range and Availability

- Stock levels of common sizes

- Special order capabilities

- Lead times for delivery

- Emergency supply options

- Storage facilities

Service Quality Indicators

- Response time to enquiries

- Technical support availability

- After-sales service

- Quality guarantees

- Returns policy

Look for suppliers who maintain detailed product documentation and can provide material test certificates. A reliable supplier should offer guidance on proper handling, storage, and installation methods specific to your project requirements.

Consider establishing relationships with multiple suppliers to ensure consistent availability and competitive pricing. Local suppliers often provide advantages in terms of quick delivery and personalised service, while larger national suppliers might offer better prices for bulk orders.

Should You Buy Reo Bars Online or Locally?

The decision between purchasing reo bars online or from local suppliers impacts your project’s budget, timeline, and logistics. Each option has its own advantages and challenges worth considering.

Benefits of Buying Reo Bars Online:

- Access to competitive pricing due to reduced operational costs

- Ability to compare prices across multiple suppliers quickly

- Convenient ordering process with 24/7 availability

- Detailed product specifications and documentation readily available

- Direct shipping to your construction site

- Bulk order discounts often available

Advantages of Local Suppliers:

- Physical inspection of materials before purchase

- Immediate availability for urgent requirements

- Face-to-face technical support and advice

- Simplified returns process if needed

- Building relationships with local suppliers

- Supporting local businesses and economy

Online suppliers typically maintain lower overhead costs, allowing them to offer more competitive prices. These savings come from reduced warehouse space, fewer staff members, and streamlined operations. Many online suppliers also leverage bulk purchasing power across multiple regions to secure better rates.

Local suppliers excel in providing personalised service and quick solutions for unexpected material needs. They often maintain stock levels based on regional construction trends and can advise on local building requirements.

Price Comparison Tips:

- Request quotes from both online and local suppliers

- Factor in delivery costs and minimum order quantities

- Consider lead times and storage requirements

- Ask about bulk purchase discounts

- Check warranty terms and return policies

- Verify product certification documentation

The choice between online and local purchasing often depends on your project’s specific requirements, timeline, and budget constraints. Some construction managers opt for a hybrid approach, maintaining relationships with local suppliers while leveraging online platforms for bulk orders and specialised materials.

What Other Factors Should You Consider When Buying Reo Bars?

Quality assurance and reliable customer support stand as crucial elements when selecting your reo bar supplier. Here’s what you need to focus on:

Customer Support Excellence

- Access to technical expertise for project-specific guidance

- Prompt response times for quotes and enquiries

- Clear communication channels for order tracking

- Availability of after-sales support

- Ability to handle custom orders and specifications

Quality Assessment Checklist

- Inspect the reo bars for uniform surface texture

- Check for proper ribbing patterns that ensure concrete bonding

- Verify the absence of rust, pitting, or surface defects

- Confirm the presence of manufacturer markings and grade identification

- Request material test certificates for quality verification

Documentation Requirements

- Material compliance certificates

- Mill test reports

- Product traceability documentation

- Quality assurance certifications

- Warranty information

Supply Chain Considerations

- Stock availability for urgent requirements

- Delivery capabilities and logistics support

- Storage facilities and handling procedures

- Batch consistency across multiple orders

- Supply chain transparency

The supplier’s ability to provide comprehensive technical support becomes particularly valuable when dealing with complex construction specifications. You’ll want a supplier who can assist with:

- Material grade selection

- Quantity calculations

- Installation recommendations

- Project-specific requirements

- Regulatory compliance guidance

A reliable supplier should maintain detailed records of all quality control measures and be willing to share this information upon request. This transparency helps ensure you receive reo bars that meet your project’s structural requirements and safety standards.

How Do You Ensure Compliance With Industry Standards When Purchasing Reo Bars?

Industry standards are important benchmarks for determining the quality and performance of reo bars used in construction projects. In Australia and New Zealand, the AS/NZS 4671 standard is applicable, while the British Standard BS4449/2005 is relevant in the UK. These standards outline specific requirements for reinforcing steel used in concrete structures.

Key Requirements Under AS/NZS 4671:

- Minimum yield strength specifications

- Tensile strength requirements

- Chemical composition limits

- Surface geometry standards

- Ductility class classifications

BS4449/2005 Compliance Points:

- Material properties and testing methods

- Manufacturing process controls

- Product identification and traceability

- Quality assurance requirements

- Technical delivery conditions

You can verify compliance through:

- Certificate Verification

- Request test certificates from suppliers

- Check for accredited laboratory testing results

- Verify batch numbers match delivered products

- Physical Inspection

- Look for clear grade markings

- Check for proper ribbing patterns

- Examine surface condition

- Measure bar diameters

- Documentation Requirements

- Material test reports

- Mill certificates

- Quality assurance documentation

- Supply chain traceability records

Reputable suppliers maintain comprehensive documentation systems to demonstrate compliance with these standards. You should request relevant certificates and documentation before finalising your purchase. These documents provide essential information about the reo bars’ mechanical properties, chemical composition, and manufacturing processes.

Working with suppliers who maintain ISO 9001 certification adds an extra layer of quality assurance. This certification indicates the supplier follows internationally recognised quality management practices in their operations.

What Are The Benefits Of Choosing High Tensile Strength Reo Bars For Your Construction Project?

Tensile strength defines a reo bar’s ability to resist breaking or deforming under tension. This crucial property determines how much stress your reinforcement can handle before failing, making it essential for structural integrity.

High tensile strength reo bars offer significant advantages for your construction project:

1. Enhanced Load-Bearing Capacity

- Support heavier structural loads

- Allow for reduced bar diameter requirements

- Enable more efficient material usage

2. Superior Crack Prevention

- Resist deformation under stress

- Maintain structural stability

- Minimise concrete cracking risks

3. Cost-Effective Solutions

- Require fewer bars for equivalent strength

- Reduce labour costs during installation

- Lower transportation expenses

4. Improved Durability

- Extended structure lifespan

- Better resistance to environmental factors

- Reduced maintenance requirements

When selecting high tensile strength reo bars, consider these grades:

Standard Grades

- 250MPa: Basic structural applications

- 400MPa: Common commercial projects

- 500MPa: High-performance requirements

Your choice of tensile strength directly impacts project success. Higher grades provide enhanced structural performance while potentially reducing material quantities needed. This balance between strength and efficiency makes high tensile reo bars an attractive option for both small residential builds and large commercial developments.

Remember to verify your supplier’s certification for tensile strength requirements, ensuring your chosen reo bars meet project specifications and local building codes.